|

| October 28, 2014 | Volume 10 Issue 40 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Gearmotor cuts assembly time, improves performance of coffee roaster

A coffee equipment manufacturer has been designing coffee roasters for decades using a chain and sprocket system. Due to the cumbersome alignment and installation of this system, the manufacturer was seeking an alternative solution to reduce manufacturing time and lower total installed cost of their new equipment.

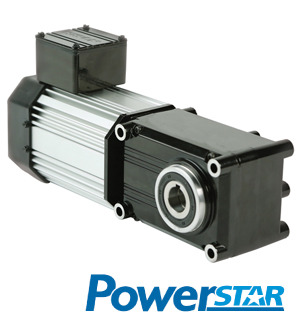

Bison Gear and Engineering met with the manufacturer to discuss these issues, sharing the benefits of the new PowerSTAR AC hypoid gearmotor and suggested it would be an excellent solution for their new system.

To provide some background on the application, the chain/sprocket configuration was initially selected for a number of reasons. First, the manufacturer needed the ability to adjust for different output speeds to match different types of coffee beans. The chain/sprocket assembly allowed for speed control by changing sprocket sizes. Second, temperature created by the rotating roasting drum originally prohibited a direct drive system, since it would cause failure after a short period of time. Finally, the cost of an alternate system in comparison with chain and sprockets discouraged the manufacturer from pursuing it.

In one iteration, the original chain/sprocket design of the coffee roaster was modified to include a remotely mounted gearmotor, but it kept the same overall functionality (interchanging sprocket sizes to control the speed). The gearmotor required additional mounting, framing, and alignment. This increased install time and cost, resulting in the manufacturer looking for ways to further improve the coffee roaster.

The Bison engineering team saw this as an opportunity to provide a complete solution for the manufacturer's new design. After meeting with their design team to better understand the criteria and performance issues, Bison recommended their PowerSTAR right-angle hypoid gearmotor as a direct drive system -- replacing the current design.

PowerSTAR is a perfect solution for this application. The gearmotor is equipped with advanced hypoid gearing technology that ensures efficient, quiet, and cool operation. The PowerSTAR also features imperial and metric mounting configurations to facilitate an easier installation.

Using the PowerSTAR in a direct drive configuration for the rotating drum would save the manufacturer on installation and alignment costs, as well as improve energy efficiency. While the manufacturer was impressed, they still considered heat created by the drum to be a gating factor when implementing a direct drive system. To confirm the unit would perform, Bison agreed to provide sample PowerSTAR units to test their performance within the application.

The initial benefits of PowerSTAR were realized early on in the test. The transition between the initial design to a direct drive system resulted in dramatically reduced install components. The eliminated components also yielded a reduced installation time since there were fewer sub-assemblies to mount and align. The PowerSTAR also proved the robustness of its design throughout the testing phase, and was specified into the new coffee roaster design.

The PowerSTAR AC unit comes in imperial and metric configurations. Standard models include: Single-Phase 115V, Three-Phase 230V, Single-Phase 115V/230V Dual, and Three-Phase Inverter Duty 230/400-460V 50/60 HZ.

Source: Bison Gear and Engineering Corp.

Published October 2014

Rate this article

View our terms of use and privacy policy